To learn more about the socks

First of all, what are socks?

There are three types of fabrics commonly referred to as "fabrics" in the world. One is woven fabric, then knitting, and finally non-woven fabric, commonly known as felt.

Woven fabric is made by combining warp and weft threads, as is the case with jeans. Therefore, unless the fibers themselves are elastic, the fabric becomes practically non-stretchable.

Knitting essentially involves creating fabric by forming loops with yarn while knitting it in a spiral. That's why knitting is elastic. People usually think of sweaters and other knitted items, but you may not know that T-shirts and similar items are also made from knitted fabric, giving them a slight elasticity. Thus, socks, tights, and stockings are all fundamentally "knit products." In the case of socks, they are usually knitted in a spiral from the elastic cuff to the toes.

Socks are knitted, just like sweaters and scarves. Knitting can be undone to recover the yarn.

As shown in the photo above, typical surface yarns such as cotton, linen, silk, wool are integrated with lining yarns such as nylon and polyurethane. It is possible to knit socks using only warp threads (such as 100% cotton or 100% wool, for example). However, this can result in a less precise fit and reduced durability.

The ideal comfort in socks is actually achieved by incorporating weft threads. For example, Tabio creates socks by incorporating primarily surface yarns made of high-quality natural fibers, as well as elastic weft threads of polyurethane wrapped in durable nylon. This combination allows for the production of socks that offer a perfect fit and great durability.

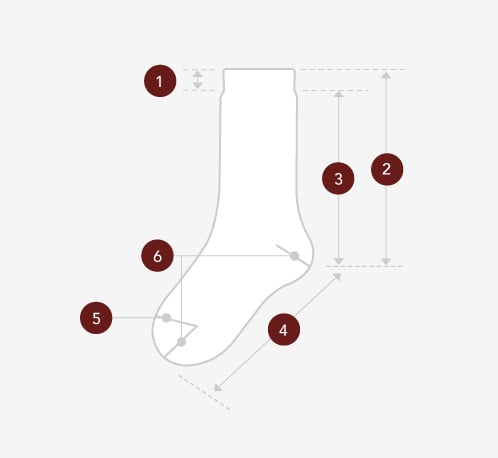

Anatomy of socks

- 1 Elastic top

- The section from the elastic rim to the start of the leg section.

- 2 Body

- The section between the heel and the heel

- 3 "Leg"

- The section from the end of the elastic top to the top of the heel.

- 4 Sole

- The section from the end of the heel to the linking; the section below the gore line that connects the heel to the end of the toe.

- 5 Linking / Rosso

- The seam of the toe. There are two ways of connecting the toe part.

- 6 "Gore line"

- The line that forms the section from the heel to the toe. The knitting switches to a semi-circle movement to create the shape of the heel.

Heels and toes

As a result, this means that socks don't slip inside shoes, and there's ample space for the toes, avoiding any "too tight" sensations, ensuring a standard quality.

*Attention

Due to the strict construction of our gusset line, Tabio socks may appear larger in the heel and toe compared to other brands. The fabric that fits the foot may be visible, which could give the impression of a larger size. However, rest assured that we produce them in accordance with the indicated foot size, so please feel free to choose your own size without worry.

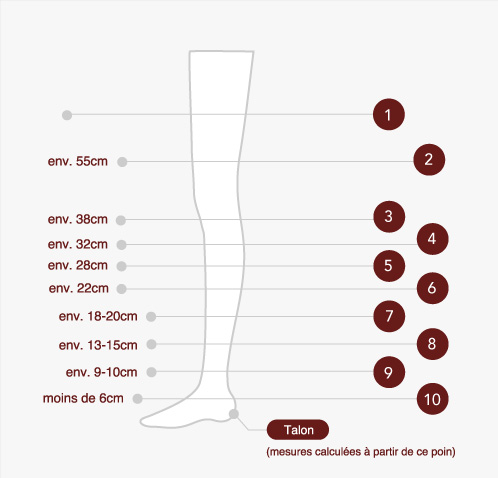

Lengths

- 1 CB

- Chaussette bas / Thigh High

- 2 CL

- Chaussette longue / Over The Knees

- 3 CH

- Chaussette haute / High Socks, Knee High

- 4 CBT

- Chaussette botte / Boot Socks

- 5 CMH

- Chaussette mi-haute / High Cut

- 6 3/4L

- Chaussette 3/4 long / Three Quarter Sleek

- 7 MC

- Mi-chaussette / Crew

- 8 CB

- Chaussette basse / Low Crew

- 9 SQ

- Socquette / Anklet

- 10 CC

- Chaussette courte / Trainer, Sneaker

*Long socks are also called "Parisiennes"..

Knitting gauge

- Number of needles (N: Needle)

The thickness of the yarn and the number of needles used by the machine will make the knitted fabric thicker or softer.

- High gauge 200N or more

A very fine yarn is used on these needle-intensive machines. The fineness of the fabric gives the sock an elegant and silky appearance. A high gauge was mainly used for men's socks, but is now increasingly used for women's socks. Tabio uses very fine cotton yarn, without losing comfort.

- Middle gauge 132N - 180N

This is the most commonly used method and is ideal for producing socks with close stitches. Typical examples of socks made in this way are socks with or without 168N ribs, or socks with striped patterns. A medium gauge fabric is used to produce a smooth looking fabric of medium thickness, the resulting sock is sufficiently elastic to fit the shape of the foot.

- Low gauge 48N - 96N

A thick natural yarn (or rolled to make it thick) is usually used on machines with few needles. Thick, uneven fabric can give the sock a "hand knitting" and softer look. This makes for traditional thick socks with a homemade look and for everyday socks.

Elastic thread at Tabio

In general, socks commonly incorporate a "elastic thread" partially to prevent slipping while wearing. The commonly used "elastic thread" in many products is either "natural rubber," which is less durable, or "polyurethane elastic," which provides a slightly less snug fit (commonly known as Spandex).

Most of the socks we offer use a high-quality "special elastic thread  (NDX)" that combines the advantages of both soft stretchability, stretching and returning to shape, and durability against wear and washing. This makes them less likely to slip and ensures a comfortable fit.

(NDX)" that combines the advantages of both soft stretchability, stretching and returning to shape, and durability against wear and washing. This makes them less likely to slip and ensures a comfortable fit.

Furthermore, this elastic thread is covered with soft rayon material for a gentle touch. There are various types and thicknesses of elastic threads, and we select the appropriate elastic thread for each application to create comfortable wear products.

Main materials used for socks

- Cotton/acrylic blend

- Thanks to the cotton/acrylic blend, the fabric remains soft after washing.

- Cotton/polyester blend

- The polyester blend allows the cotton to keep its shape and prevents it from shrinking in the wash.

- Cotton/linen blend

- The addition of cotton to linen makes it softer and more elastic.

- Wool/acrylic blend

- The wool/acrylic blend gives a fabric that is warm, soft and strong, and absorbs perspiration well.

- Wool/nylon blend

- Wool/nylon blend increases the life of the product and makes it easier to wash.

- Fur/synthetic blend

- The use of pure natural materials such as angora, mohair or cashmere are difficult in themselves. The addition of wool or a synthetic fibre facilitates the weaving and the fit of the garment.

- Silk filament

- Raw silk thread extracted directly from the cocoons of silkworms consists of the highest quality yarn.

- The silk boulette

- This yarn is obtained by weaving the remaining silk threads after spinning the filament.

Description of materials [Natural fibres]

- COTTON

- Characteristics

A fluffy fibre that grows around the cotton seed. This fibre is spun to produce a yarn that will make a light and airy fabric. Highly absorbent, cotton can hold 24-27 times its weight in water and is more resilient when wet.

Advantages

It withstands very high washing temperatures, absorbs and releases perspiration quickly allowing the fabric to breathe. It is a strong and durable fabric that is highly resistant to abrasion. - LINEN

- Characteristics

It is a fabric made from the fibres of the flax plant. Linen is one of the strongest plant fibres and is 2 to 3 times stronger than cotton.

Advantages

Linen is a good conductor of heat, has a high absorption capacity and is cool to the touch. On the other hand, it is not very elastic and creases easily. - LAMB'S WOOL

- Characteristics

Lamb's wool comes from young animals (6-7 month old lambs) and is characterised by a short hair.

Advantages

Softer than sheep's wool, it is warm and pleasant on the skin. This wool is very durable, does not wrinkle and absorbs moisture very well. - SILK

- Characteristics

Silk is a natural fibre from China that is soft and smooth but does not slip. It is one of the strongest natural fibres, but loses 20% of its strength when wet. Silk has a medium to low elasticity and is sometimes replaced by rayon, which is less expensive.

Silk is particularly pleasant and shiny, very comfortable and extremely soft on the skin. - ANGORA

- Characteristics

This fibre, which comes from rabbit hair, is fragile, has low elasticity and strength, which makes it difficult to colour. Angora fibre is hollow, which explains its floating appearance.

Advantages

Gentle on the skin and warm, this fibre is renowned for its silky texture. - CASHMERE

- Characteristics

An animal fibre from the goat raised in the mountains of Kashmir, this wool tends to pilling and attract moths. It is very delicate to care for and cashmere garments are best stored flat.

Advantages

Fine in texture, light and soft, this fibre is also very hardwearing and can last a long time if cared for properly. - TENSHO MINERAL FIBRE

- Tensho fibre is a natural fibre of mineral origin made from stone from the southern region of Japan. It has remarkable heat-generating properties thanks to the infrared rays naturally emitted by this stone.

Material description [Artificial/Synthetic fibers]

- ACRYLIC

- Characteristics

This fabric wrinkles easily and tends to pilling.

Advantages

Durable, acrylic is unaffected by grease or chemical compounds and is highly UV resistant. It is also light, soft and warm. - NYLON

- Characteristics

Nylon is highly elastic and has enabled the development of easy-care materials. Highly resistant to abrasion and chemical compounds, nylon is easily coloured.

Benefits

Bright and lightweight, it is comfortable and soft. - POLYESTER

- Characteristics

Polyester fabrics have several advantages over natural fibres. They are more durable, retain colours better and are difficult to crease. Polyester fibres are sometimes blended with natural fibres to produce a fabric with mixed properties.

Advantages

In contrast to plant-based fibres, synthetic fibres provide materials that are more resistant to water, wind or specific environmental conditions. - VISCOSE/RAYON

- Rayon is a chemically recomposed cellulosic fibre. Produced from natural polymers, rayon is a semi-synthetic or artificial material. Also known as "artificial silk" or "viscose" in the textile industry, rayon is very shiny and gives the fabric a glossy appearance.

- CUPRA

- Cupra is a new fibre obtained from a process similar to that of rayon and composed of cellulose.

- ACETATE

- Acetate is an artificial or synthetic fibre with an extremely silky appearance. It dries quickly and absorbs moisture very well. Most fabrics made of acetate need to be dry cleaned. Acetate is usually used for clothing and home furnishings.

- POLYURETHANE

- Characteristics

Highly elastic, polyurethane is the lightest of all fibres and produces a very fine yarn.

Advantages

This material is very resistant, especially to UV, heat and chemical compounds.

Washing socks

Please refer to the label. Hang them in a ventilated area by the elastic band.

- Machine wash

- - Maximum temperature 40°

- - Delicate cycle, maximum temperature 40°

- - Delicate cycle, maximum temperature 30°

- Hand wash

- - Hand wash, maximum temperature 30° with suitable detergent

*Wash your socks in warm water

- Blanching

- - Use a mild detergent

- - Do not use a chlorine-based bleach

- Spinning

- - Squeeze carefully

- - Do not spin socks too hard

- Drying

- - Make them dry in the shade

For more information on washing, we invite you to read this page, « How to care ».

Women

Women

Men

Men

Bulk Discount - 100% cotton

Bulk Discount - 100% cotton

Bulk Discount - Colour tights

Bulk Discount - Colour tights

Bulk Discount - 3+1

Bulk Discount - 3+1

LEG LABO

LEG LABO

INVISIBLE

INVISIBLE

TABI / TOE SOCKS

TABI / TOE SOCKS

Marathon / Running

Marathon / Running

Football

Football

Basketball

Basketball

Cycling

Cycling

Golf

Golf

Baseball

Baseball

Fitness

Fitness

Business

Business

All Embroidery service

All Embroidery service

Broderie standard

Broderie standard

Graphic embroidery

Graphic embroidery

All Anti-slip

All Anti-slip

Gift wrapping

Gift wrapping

Non-elastic

Non-elastic

New arrivals

New arrivals

PREMIUM

PREMIUM

Bulk Discount

Bulk Discount

WOMEN

WOMEN

MEN

MEN

TABI / TOE SOCKS

TABI / TOE SOCKS

SPORT

SPORT

KIDS

KIDS

Personalization

Personalization

Accessories

Accessories